Reference material for king pin to ball joint conversion

I'm going to put links and info here that pertains to the ball joint conversions. It won't be in any particular order.

Do your own "due diligence"!! You are responsible for verifying any of this info before installation. I'm providing this info as a guide and to point you in the right direction. It's not meant to be a comprehensive, step by step instruction. If you're unsure or don't understand how to do any of this, seek professional help. Do not email me about which bearings to use. If you can't figure out which bearings to use, you should not be doing this conversion.

Do your own "due diligence"!! You are responsible for verifying any of this info before installation. I'm providing this info as a guide and to point you in the right direction. It's not meant to be a comprehensive, step by step instruction. If you're unsure or don't understand how to do any of this, seek professional help. Do not email me about which bearings to use. If you can't figure out which bearings to use, you should not be doing this conversion.

Final walk through video

Spindle Assembly

This conversion is designed around the Nissan Hardbody(D21) spindle. The best spindles are between 12/85(720 model) and 1997. The prior year spindles can be used, just not preferred. The 620 spindle used non-vented rotors. The 720 models used a rotor with a shorter top hat which limits wheel choices due to caliper clearance. Any of the disc brake hubs, 620/720/HB, can be used on the HB spindle(or dropped spindle) with the HB rotor/caliper. The preference is to use HB rotors since the offset allows stock 14" steel rims to be used(NOTE: check the info further down about the hubs). If you want the easiest, least expensive option, just obtain the entire HB spindle assembly. Disconnect the two ball joints, the tie rod and brake hose. Remove it all as one unit.

If you want a lower ride height, now would be the time to buy dropped spindles. All the dropped spindles that I've see are HB spindles. If they're getting put on a 720, there are two spacers to offset the caliper to work with the 720 rotor. Just change to an HB rotor and skip the spacers. Here's a link I got from a post made by Steve F. (Redeye) on Ratsun.net. It's Belltech's installation instructions. Take note of item 19.

http://www.belltech.com/extras/docs/BBGC/2010.pdf

If you're looking to run the stock 14" steel rims, the early 620 and early 720 hubs are the best since they'll fit the center hole of the rim. The later hubs have a larger nose diameter and will need to be ground or machined to fit the center hole. More info about the hubs is here: Hub Info

5 lug option. Once you have HB spindles, you can convert to 5 lug Toyota hubs. The info about that is here: 5 Lug Options

If you want a lower ride height, now would be the time to buy dropped spindles. All the dropped spindles that I've see are HB spindles. If they're getting put on a 720, there are two spacers to offset the caliper to work with the 720 rotor. Just change to an HB rotor and skip the spacers. Here's a link I got from a post made by Steve F. (Redeye) on Ratsun.net. It's Belltech's installation instructions. Take note of item 19.

http://www.belltech.com/extras/docs/BBGC/2010.pdf

If you're looking to run the stock 14" steel rims, the early 620 and early 720 hubs are the best since they'll fit the center hole of the rim. The later hubs have a larger nose diameter and will need to be ground or machined to fit the center hole. More info about the hubs is here: Hub Info

5 lug option. Once you have HB spindles, you can convert to 5 lug Toyota hubs. The info about that is here: 5 Lug Options

Alignment Info

I received this info from Mark Stein Innovations www.msimotorsports.com also on instagram.com/msinnovations/

For a “street car”, your optimum camber is going to be somewhere between -0.25 to -0.75, still giving good tire wear and good handling. As far as caster goes, for non-power steering, 3 to 4 degrees of positive caster works well. Don’t forget that because of road crown, you’ll want to run about a ½ degree more caster on the passenger side than the driver’s side to make the vehicle track straighter down the road. With this setup, you want about a ½-1 degree of negative camber at full compression.

For a “street car”, your optimum camber is going to be somewhere between -0.25 to -0.75, still giving good tire wear and good handling. As far as caster goes, for non-power steering, 3 to 4 degrees of positive caster works well. Don’t forget that because of road crown, you’ll want to run about a ½ degree more caster on the passenger side than the driver’s side to make the vehicle track straighter down the road. With this setup, you want about a ½-1 degree of negative camber at full compression.

Coil Over Info

This is just an example, based on what was used during the design.

Proshocks ASB series ASB/SR3AU(satin), ASB/SR3AUP(polished), 3" stroke, 8.5" compressed, 11.5" extended, 10.5" ride height, 7-8" tall springs.

COIL SPRING: Item #: 27300-1CR

Extreme Chrome Spring Coil-Over 2-5/8 Inch Inside Diameter 300 Lbs./Inch Rate 7 Inch Length

Proshocks ASB series ASB/SR3AU(satin), ASB/SR3AUP(polished), 3" stroke, 8.5" compressed, 11.5" extended, 10.5" ride height, 7-8" tall springs.

COIL SPRING: Item #: 27300-1CR

Extreme Chrome Spring Coil-Over 2-5/8 Inch Inside Diameter 300 Lbs./Inch Rate 7 Inch Length

Tie Rod Assemblies

I had to refer to this info myself and realized, it's not very easy to see. There are five different part numbers. Four of them are the tie rod ends, the fifth is the barrel connector(turnbuckle). The "left" and "right" denote the thread direction, not the side of the vehicle. For the turnbuckle connector to work, it needs a left hand threaded tie rod on one end and a right hand threaded tied rod on the other. For example, a long, left tie rod needs to be used with a short right tie rod. For the turnbuckle to rotate in the same direction on the other side of the vehicle, it will need to have a long right paired with a short left.

Short, RH thread: ES3114 or Spicer 401-1415

Short, LH thread: ES3115 or Spicer 401-1416

Long, LH thread: ES3116 or Spicer 401-1414

Long, RH thread: ES3117 or Spicer 401-1417

Turnbuckle/coupler/connector: ES2900S

Short, RH thread: ES3114 or Spicer 401-1415

Short, LH thread: ES3115 or Spicer 401-1416

Long, LH thread: ES3116 or Spicer 401-1414

Long, RH thread: ES3117 or Spicer 401-1417

Turnbuckle/coupler/connector: ES2900S

LCA removal

I just came across this video on my YT channel and figure this would be a good place for it.

LCA Inner Bushing Info

If you're a glutten for punishment and really feel it's necessary to replace the LCA inner bushings, here's some vids for a bit more info.

I found a post I made on Ratsun.net that included links to IG posts I made. I'm going to put a link to the post here to make finding it again much easier.

https://ratsun.net/topic/75352-ball-joint-conversion/?do=findComment&comment=1695308

I'll paste the post here, but I'm not sure I'll do all the links. You can either go to the post with the above link or copy/paste them from below.

Posted January 31, 2021 (edited)This is everything that has been posted to IG already. I'll try to keep updating this as I go. Although, there is some consideration being given to completely getting off of social media...at least FB and IG.

Couple of notes. If you see dots at the bottom of the pic/video, that means there's more than one page. If so, there should be an arrow on the right side in the middle. Clicking the arrow moves you to the next pic/vid. Some have just one, others can have up to 10. For sound, there should be a black button at the bottom right with a speaker icon. It should be slashed out to start with, then when you click on it, the slash goes away and you'll get sound. I hope this works ok. I really don't have the time to mess with this much.

Cutting LCAs, starting

https://www.instagram.com/p/CI6KNG8Jr-u/?utm_source=ig_web_button_share_sheet

Still cutting LCAs, measuring

https://www.instagram.com/p/CI_epRBJWKq/?utm_source=ig_web_copy_link

Bandsaw cutting LCA

https://www.instagram.com/p/CJCnwU3Jff_/?utm_source=ig_web_copy_link

Marking sway bar hole

https://www.instagram.com/p/CJHRpz8JCbX/?utm_source=ig_web_copy_link

Machining sway bar hole

https://www.instagram.com/p/CJHSVhZJ7JM/?utm_source=ig_web_copy_link

Removing bottom plate with cnc mill and old cutter/endmill

https://www.instagram.com/p/CJMbtH2pLP4/?utm_source=ig_web_copy_link

Bottom plate, but with new cutter

https://www.instagram.com/p/CJWYPRcpgqg/?utm_source=ig_web_copy_link

Dealing with differences between parts from rockauto

https://www.instagram.com/p/CJhCvZNJhkq/?utm_source=ig_web_copy_link

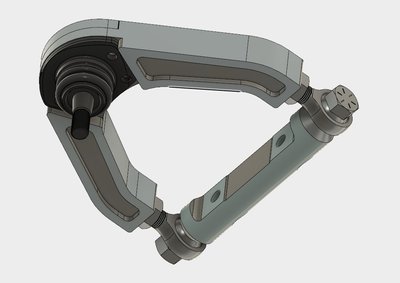

3D print for UCA Xshaft test

https://www.instagram.com/p/CJwNAgApLLm/?utm_source=ig_web_copy_link

LCA bore for cup

https://www.instagram.com/p/CJwYnrppjuE/?utm_source=ig_web_copy_link

3d print finished, removing from bed

https://www.instagram.com/p/CJxVhyCpac-/?utm_source=ig_web_copy_link

3D print close up of hole and threading

https://www.instagram.com/p/CJzQ0l8Jvde/?utm_source=ig_web_copy_link

3D print on frame

https://www.instagram.com/p/CJzRNa9pK5w/?utm_source=ig_web_copy_link

More about LCA bore for cup

https://www.instagram.com/p/CJzfwKqJ8XQ/?utm_source=ig_web_copy_link

Even more about LCA bore

https://www.instagram.com/p/CJ1iqd7p0b-/?utm_source=ig_web_copy_link

3D print for lathe chuck depth stop to make the LCA cups

https://www.instagram.com/p/CJ3z0FGJp_A/?utm_source=ig_web_copy_link

Prepping stock for the cups

https://www.instagram.com/p/CKE70-hJWp7/?utm_source=ig_web_copy_link

Depth stop on lathe

https://www.instagram.com/p/CKFNdFnp9Kg/?utm_source=ig_web_copy_link

Cutting side one of the cups on the lathe

https://www.instagram.com/p/CKFPxiFpRR-/?utm_source=ig_web_copy_link

Start of mill work on cups.....oops

https://www.instagram.com/p/CKHqPnuJiPY/?utm_source=ig_web_copy_link

Cups being milled out

https://www.instagram.com/p/CKKM3E1poTN/?utm_source=ig_web_copy_link

Gusset prep for underside of LCAs

https://www.instagram.com/p/CKPSnJjJBQg/?utm_source=ig_web_copy_link

Over an hour of welding and barely half done on a set of arms (pic)

https://www.instagram.com/p/CKZuQ0FJ8TK/?utm_source=ig_web_copy_link

Laser cut parts for the LCAs

https://www.instagram.com/p/CKown86pk7h/?utm_source=ig_web_copy_link

Welding setup info

https://www.instagram.com/p/CKrbI_-JKsK/?utm_source=ig_web_copy_link

Couple of weld pics....nothing to write home about.

https://www.instagram.com/p/CKrrDSzpA2U/?utm_source=ig_web_copy_link

Look at coil over and shock

https://www.instagram.com/p/CK9oox4pQsl/?utm_source=ig_web_copy_link

Upper shock reinforcement

https://www.instagram.com/p/CLIN7N2p3gd/?utm_source=ig_web_copy_link